Engagement Options

1. Rapid Diagnostics for Turnarounds

·Typical duration*: 2 to 4 weeks

·Best for: urgent performance constraints, unclear bottlenecks,

recurring firefighting

·Outputs: current-state diagnosis, quantified constraint,

prioritised turnaround plan, quick wins, decision pack for

leadership

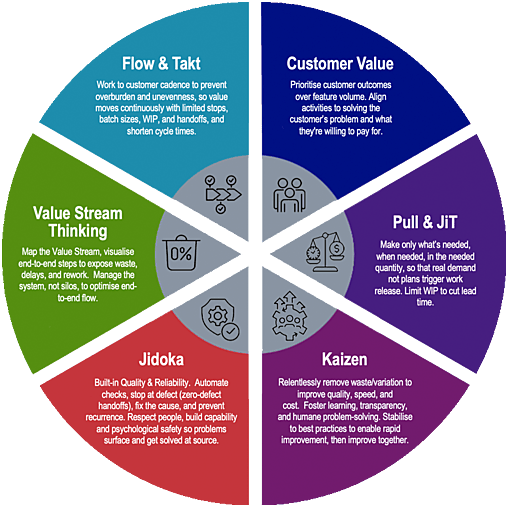

2. Flow and Speed (Lean) improvements

·Typical duration*: 4 to 12 weeks

·Best for: long lead times, queueing, handoffs, rework loops,

poor predictability

·Outputs: redesigned flow, standard work, and visual

management, capacity, and bottleneck plan, cadence for daily

management

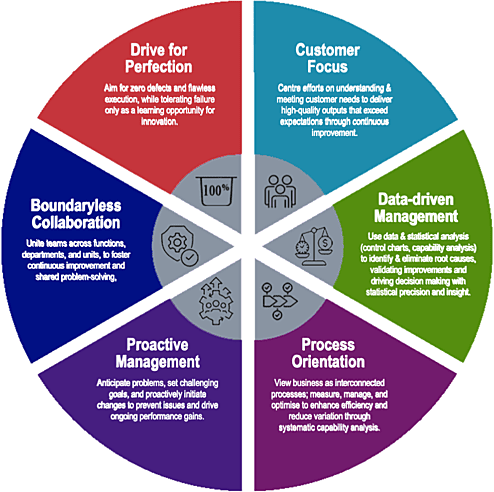

3. Quality & Variation (Six Sigma)improvements

·Typical duration*: 8 to 16 weeks

·DMAIC framework adopted

·Best for: defects, instability, hidden variation, weak

measurement confidence

·Outputs: validated root cause, improved capability, control

plan, measurement, and monitoring approach that prevents

backsliding

4. Lean Governance (Gains that stick)

·Typical duration*: 4 to 10 weeks (can run alongside

improvements)

·Best for: initiatives that fade, inconsistent adherence to

standards, and poor escalation

·Outputs: governance cadence, operating system rhythms,

visibility and accountability, leader standard work, sustainment

design

*(depending on scope and complexity)

Help me choose

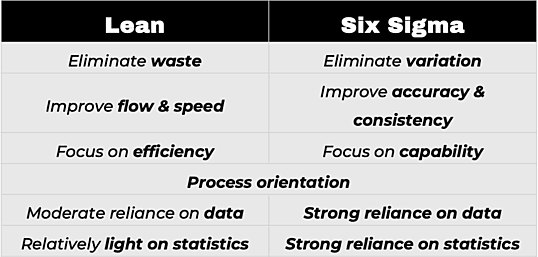

=> Is lead time or defect rate the bigger pain?

Lead time: Lean

Defect rate: Six Sigma

=> Do you have reliable measurements?

No: Measurement System Analysis (Six Sigma MSA)

=> How costly are mistakes?

Impacts throughput (flow, speed): Lean

Impacts quality (variability, consistency): Six Sigma

=> If velocity and flow are concerns:

Start with Lean. (Stabilisation)

=> If accuracy and consistency are concerns:::

Use Six Sigma. (Sustainable Capability)

=> If you need both:::

Start with Lean to stabilise first, then add targeted Six Sigma

where variation hurts outcomes (leakage of clients/profitability,

and rework/returns)

=> Can you commit budget now to resolve the issue/s?

NO: Commit funds for next budget cycle (Let us guide you)

YES: Contact Us

What you can expect

Deliverables we commonly provide

· A clear current-state picture, including constraints and impacts.

· A prioritised improvement backlog linked to measurable

outcomes.

· A focused set of implemented changes, not just

recommendations.

· A governance cadence and control plan so results are

sustained.

· Capability transfer to your team as part of the work.

What we do not do

· We do not ask for perfect data before taking action.

Skills Transfer

We deliver the following (often as part of an engagement):

1) Lean education:

- Can be done across selected Lean tools and methods;

2) Six Sigma education:

- Can be done for leaders and teams at a high level to enable

them to run effective Six Sigma projects as key stakeholders

- Clinics, workshops, and executive briefings aligned to your

project.

- White Belt, Yellow Belt, Green Belt, and Black Belt training

coming soon (It is preferable that your organisation has at

least 1 Minitab licence)