Case studies of typical projects we have helped clients with

Case 1: Plastics Packaging Manufacturing Operation - Process Efficiency & Profitability Transformation.

A plastics packaging manufacturer needed to restore flow, predictability, and profitability across a multi-process production environment. We helped stabilise planning and material availability, reduce avoidable downtime, and improve reliability from order intake through to dispatch. The result was a more controllable operating rhythm, higher throughput, better utilisation, and improved customer experience - without exposing the detailed mechanics of how the factory was tuned.

Case 2: Defence Manufacturing Process Industrialisation & Lean Transformation

A defence manufacturer was moving from prototype builds into repeatable, industrialised production of mission-configurable vehicles. We supported the transition by tightening cross-functional coordination, improving readiness of materials and work preparation, and strengthening day-to-day production management. This enabled a more repeatable delivery system with improved quality, faster issue resolution, and a practical continuous-improvement cadence suitable for a regulated environment.

Case 3: Quality Excellence and Process Transformation in Aerospace Defence Manufacturer

An aerospace defence manufacturer required a step-change in quality and flow across component manufacture, inspection, and testing in a highly regulated setting. We improved end-to-end clarity of the production system, reduced avoidable rework and delays, and strengthened feedback loops between design, production, and quality. The outcome was improved delivery confidence, stronger process capability, and faster throughput while preserving compliance.

Case 4: Catalytic Converter Manufacturer - Supply Chain and Procurement Process Transformation

A catalytic converter manufacturer needed procurement and supply chain uplift to reduce cost, strengthen supplier performance, and free production leaders from tactical buying. We established a clearer operating model for procurement, improved spend visibility, introduced structured sourcing and supplier management, and embedded pragmatic governance. This delivered savings, reduced risk exposure, and improved operational focus for the production organisation.

Case 5: Organisational Redesign & Governance Reform for an African Civil Aviation Authority

A civil aviation authority faced structural fragmentation, weak accountability, and misaligned people practices that undermined performance and trust. We helped reset organisational fundamentals, align the operating model to strategy, and introduce clearer role, performance, and governance disciplines. The result was a more coherent organisation with improved leadership leverage, stronger alignment, and a platform for sustained reform.

Case 6: Mission-Critical Credit Bureau Relationship Stabilisation & Operating Model Redesign

An Insurance client faced a mission-critical risk when a credit bureau relationship deteriorated due to aged balances and unclear ownership of accounts and users. We stabilised the relationship by clarifying account structures, improving data integrity, and enabling invoice visibility and ownership at the appropriate organisational level. This prevented service interruption and restored a workable, sustainable operating relationship.

Case 7: MRP Inventory Data Remediation & SAP Implementation Readiness Project

A cement manufacturer preparing for SAP faced major risk due to poor MRO and inventory master data quality and weak governance. We led a structured remediation and readiness effort to stabilise item master integrity, reduce duplication, and establish a sustainable codification and governance approach. The result was improved data confidence, better stock control, and reduced working-capital drag.

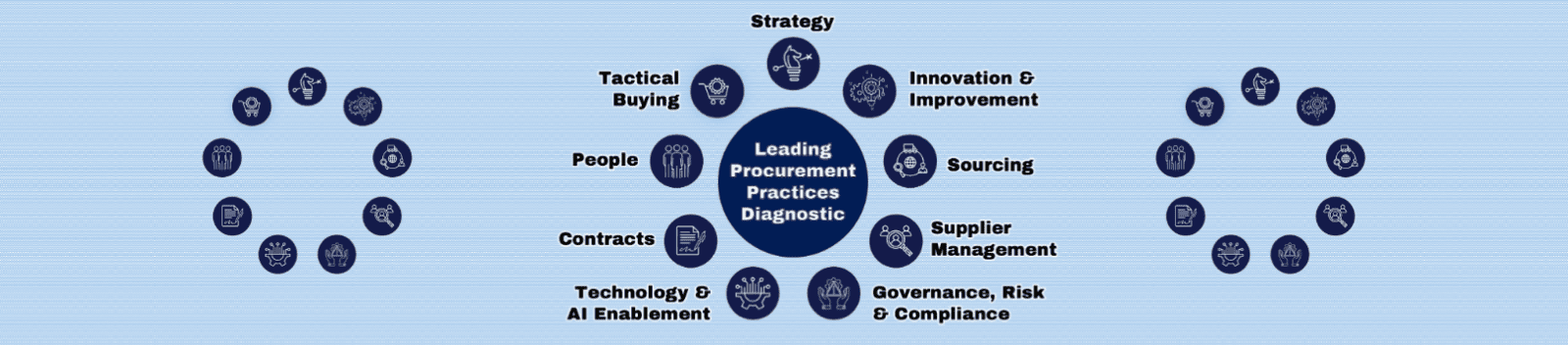

Case 8: Online Diagnostic For Procurement Excellence & Supply Chain Leverage

We developed an online diagnostic that benchmarks procurement capability against recognised leading practices and translates results into a prioritised improvement pathway. The tool helps organisations focus effort where it will create the biggest impact, rather than spreading change initiatives too thin. It supports stronger supply chain leverage, better category management, and practical progression toward procurement excellence.

Case 9: Governance, Risk Management & Compliance Enablement

We support organisations to design and implement governance, risk, and compliance instruments that are practical, auditable, and fit for their operating reality. Engagements start with structured discovery to clarify mandatory requirements, organisational interdependencies, and the governance outcomes required. We also enable capability transfer through supporting learning content and policy formulation training, improving compliance and consistency over time.For a deeper view of our work - including expanded case examples and the types of deliverables we can produce - download the Project Showcase Pack below. It is designed to help you quickly assess fit and identify where we could add value in your context.